News

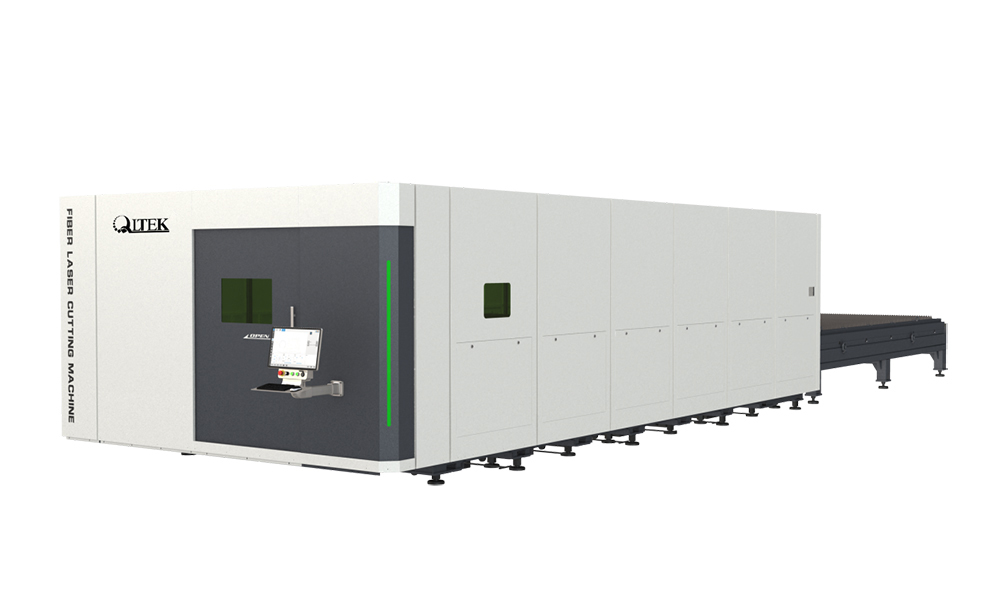

In today’s metal processing industry, where ultimate efficiency is the pursuit, true “speed” is not only about breakthroughs in motion, but also the pinnacle of system-level coordination and optimization. The all-new GI Series ultra-high-speed laser cutting machine by QLTEK delivers 3.0G ultra-high acceleration, exceptional precision, and intelligent design—overcoming technical bottlenecks of ultra-fast cutting. It brings a dual leap in both efficiency and quality to industries such as metalworking and automotive manufacturing.

As an industry pioneer, QLTEK led the market trend as early as 2019 with its high-speed models, delivering over 1,500 units. Through technological innovation and large-scale market validation, it has established itself as a benchmark in the high-end segment of the industry.

From Speed Legend to Industry Benchmark: Inheritance and Breakthrough of QLTEK

In 2019, the laser cutting industry entered a “speed race.” QLTEK’s GI Series outpaced competitors in contour cutting speed by 20%, becoming a benchmark with its innovative design and high-performance transmission system.

However, market price wars forced compromises between performance and cost, leading to reduced capabilities in some equipment. Keenly aware of market shifts, QLTEK has remained technology-driven, dedicating itself to developing the new generation of GI Series ultra-high-speed laser cutting machines. This new model not only inherits the speed superiority of previous GI models but also achieves new heights in speed, precision, and stability through system-level optimization—redefining what “fast” truly means in the industry.

1. How is “Ultra-High Speed” Achieved?

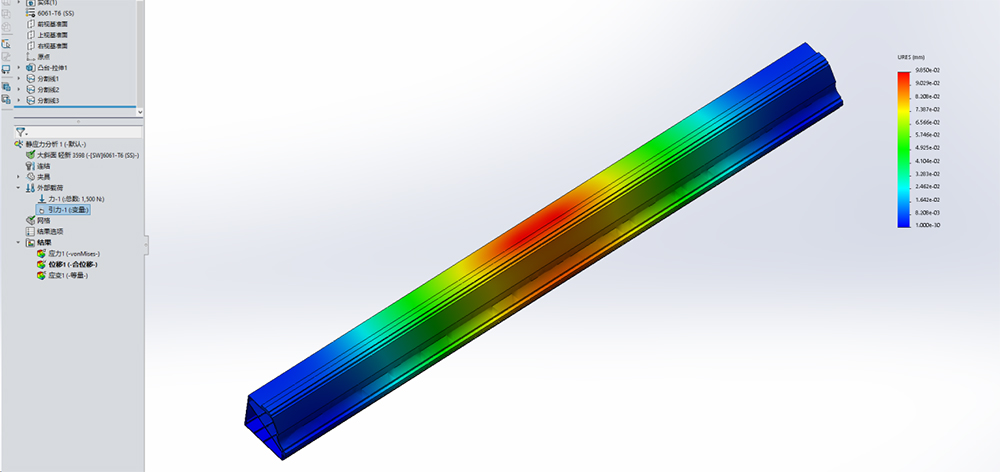

Lightweight Structure

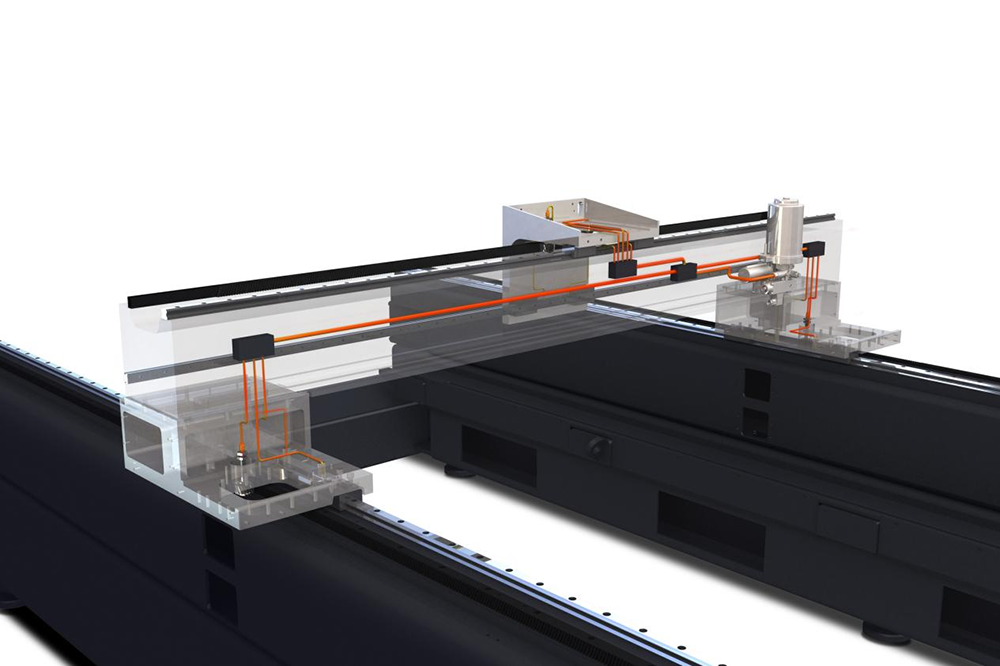

Crafted from T6061 aerospace-grade aluminum crossbeam: lightweight yet highly rigid, achieving up to 3.0G acceleration and a 40% boost in cutting speed.

The unique design effectively suppresses high-frequency vibrations, ensuring stable high-speed operation.

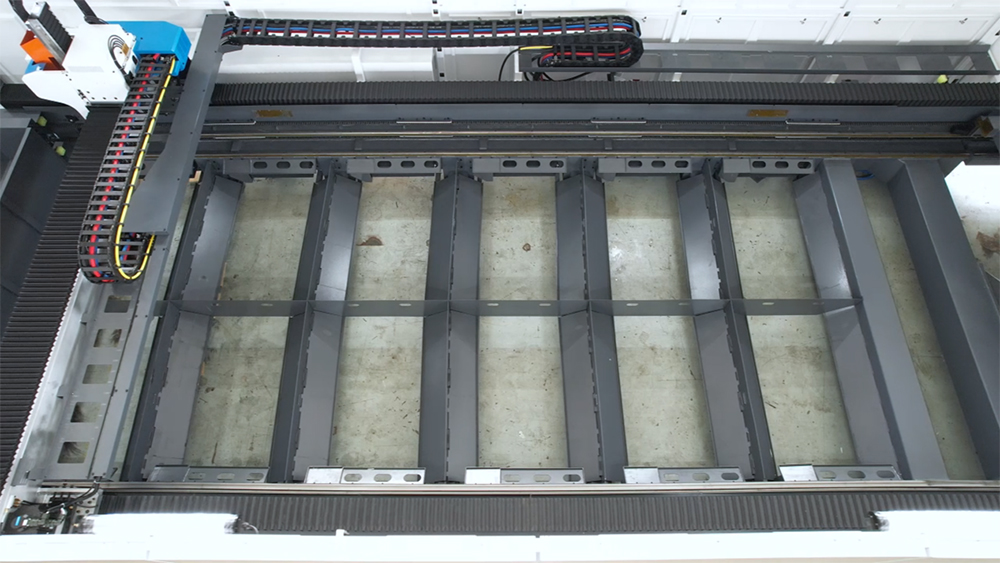

High-Performance Drive System

Equipped with high-speed servo motors, high-torque reducers, and precision guide rails.

Z-axis is specially optimized for multi-hole processing, enabling fast response and accurate cutting.

Z-Axis Gear Rack Drive

Paired with an automatic lubrication system to ensure both stability and positioning accuracy for efficient operations.

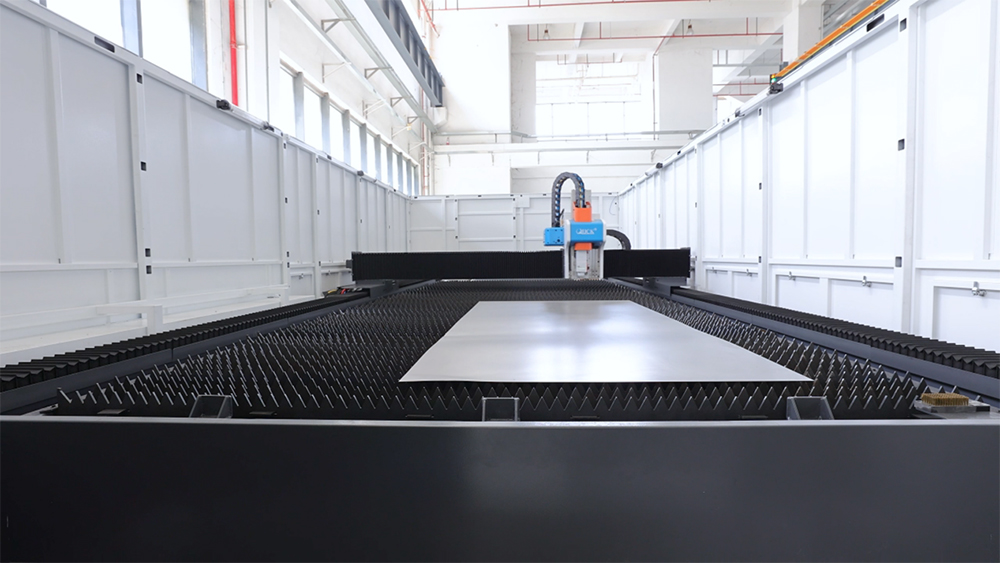

Innovative Hollow Structure

An industry-first hollow frame design that effectively isolates thermal conduction, thoroughly resolving bed vibration and thermal deformation under high-speed operations—ensuring consistent cutting precision over time.

2. How is “Long-Term Stability” Achieved at Ultra-High Speed?

Dynamic and Static Simulation Validation

Precision simulations predict vibration and structural stress to ensure scientific and reliable design.

High-Precision Assembly Process

Torque standards enhanced by 20%, assembly accuracy improved by 30%, and factory extreme testing duration extended by 50%, ensuring durability and reliability.

Smart Lubrication System

Fully automated timing and quantitative lubrication, significantly extending the lifespan of core components.

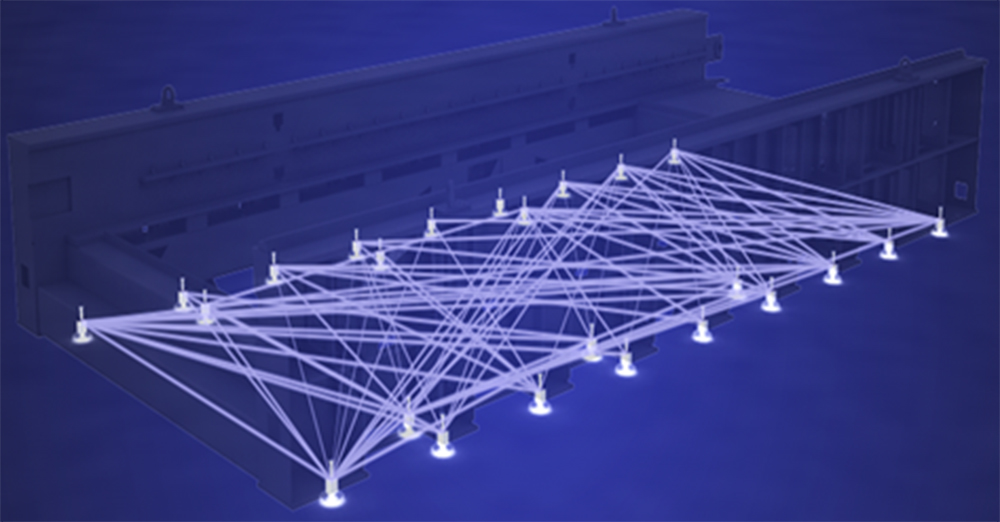

Adaptive Machine Feet Design

Innovative 2+4 cross-type structure effectively absorbs vibrations, ensuring smooth cutting and consistent accuracy throughout operations.

QLTEK’s all-new GI Series ultra-high-speed laser cutting machine redefines industry benchmarks with groundbreaking speed and stability. Whether you are in metal processing, automotive manufacturing, or other high-precision industries, the GI Series is your ideal choice for boosting efficiency and optimizing quality.

Post time: Jun-06-2025